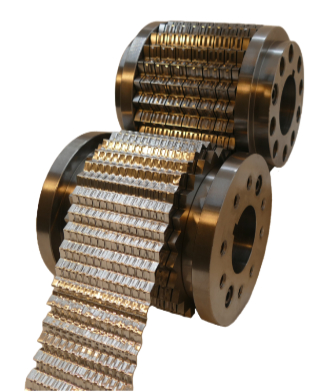

The use of rolled-formed fins is a common application used for the dissipation of heat. We find rolled-formed fins in many everyday products and quite often don’t give much thought to their use. Yet, without them, many of the products we use on a daily basis would fail due to the buildup of heat.

Eight Common Industry Applications

Rolled-formed fins are made from a variety of materials depending on the specific application. The heat transfer materials used in HVAC systems may be quite different than those used in the transfer of heat from an aerospace application. However, both are vitally important to the function of each specific product or application.

Some of the more common applications of rolled-formed fins:

1. Heat Exchangers: We find rolled-formed fins used extensively in heat exchangers used in HVAC systems or refrigeration units. To show diversity we can also find them used in power plants, chemical processing, or even in oil refineries. Heat exchangers that employ rolled-formed fins are very efficient means of transferring heat between fluids and enable effective heating and cooling.

2. Air Conditioning and Refrigeration Units: Rolled-formed fins allow the efficient transfer between the refrigerant and the surrounding air for effective cooling of the surrounding air. As such, condenser and evaporator coils use them.

3. Automotive Radiators: Rolled-formed fins provide an effective means of heat dissipation from engine coolant. The fins increase the surface area of radiator tubes and help to enable efficient cooling of fluids through the passage of air.

4. Aerospace Applications: In Aerospace, applications vary with heat transfer requirements. For example, heat exchangers for aircraft engines frequently employ rolled-formed fins. Also, oil coolers and other critical cooling systems requiring the efficient transfer of heat, use rolled-formed fins.

5. Power Generation: You will find rolled-formed fins used extensively throughout power generation plants where heat dissipation can be crucial. We find fins used in heat exchangers, condensers, and air-cooled systems to transfer heat and maintain efficiency along with optimal maintenance of temperatures.

6. Industrial Process Cooling: Rolled-formed fins within cooling systems can be found in chemical reactors, boilers, and other process equipment that requires effective temperature controls.

7. Electronics Thermal Management: Here we find rolled-formed fins in a multitude of electronic devices. Heat sinks with fins can be used to control the temperatures that can have devastating effects on electronics. Therefore, we will often find heat sinks using fins in components such as CPUs, solar equipment, power amplifiers, or LED lighting systems for example.

8. The oil and gas industry: Producers in this industry make extensive use of rolled-formed fins to dissipate heat effectively. There are critical devices that help to regulate the buildup of heat. In addition, optimization and efficiency of various processes and operations are required.

Livernois Engineering Is Ready for the Future

These are just some of the common applications using rolled-formed fins. However, we are constantly answering questions from customers about their specific applications for rolled-formed fins. As well as their temperature regulation capabilities. Livernois engineers have extensive knowledge and are committed to producing and providing the machinery needed to produce the rolled-formed fins for ideal applications. We rely upon our 70-year history to help plan for future applications.

Contact Us today to find out how we can help your company now and into the future!