Livernois provides equipment that helps in the core assembly process. There are lots of parts that go into a heat exchanger. Once you get all the parts together, it is critical to assemble them properly. The assembly of these parts ties everything together to make a heat exchanger functional. But what goes into the core assembly process? Also what equipment options do you have for core assembly?

Assembling a Heat Exchanger Core

To assemble a heat exchanger core, you need to manufacture parts. There are a number of machines and equipment needed to accomplish the assembly. The determining factor is dependent on the type of heat exchangers that are being made. If you are building a shell-and-tube heat exchanger, you will need equipment for tube expansion, tube cutting, and baffle insertion. Meanwhile, plate heat exchangers need plate stacking for flowing channels and gasket placement. Each heat exchanger needs different parts for their assemblies, especially if they are needed in specific industries.

Fortunately, there is an easy way to get everything that you need thanks to Livernois’ partnership with Tridan International and Innovation Automation! You can get manufacturing equipment for tubes, fins, and plates. Livernois has a selection of fin equipment as well. After gathering all of the parts, there are still a few things you need to do before assembly, such as leak testing and surface treatment. Once these steps are completed, you can assemble your core. Of course there are other factors and engineering considerations. In that regard, the engineers at Livernois are an excellent resource for consultation.

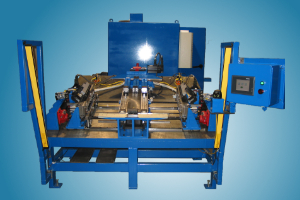

Core Assembly Equipment

When it comes to core assembly equipment, Livernois has a variety of options. All heat exchanger cores need to be built with an assembly system. However, one system can be different from another. If you are only manufacturing a small amount of heat exchangers, then you will want to use a Manual Easel system. However, if you are looking for machines that have higher manufacturing outputs, you might consider semi-automatic or automatic systems. Another option is to rebuild your assembly equipment. If you have equipment that just needs a few changes, then rebuilding one may be the best option. Livernois Engineering will help you choose the system that best fits your needs.